| e-NOTES (1608 [C] ) | ||

| 8th (Chemistry) | |||

| Synthetic Fibres and Plastics I | |||

Types of MaterialsWe may use many materials in our daily life. Some are made up of natural materials such as wood, cotton, stones and clay. A material can be used to make different kinds of things. For example: glass can be used to make bowls, tumblers, window panes etc. Types of Materials :FiberglassFiberglass is a composite material made of thin strands of glass fibers embedded in a matrix of resin. The glass fibers provide strength and reinforcement, while the resin matrix holds the fibers together and provides protection against environmental factors. Fiberglass is known for its lightweight, strength, and durability, making it a popular material in various applications. Majorly consists of silicon oxide: Fiberglass is composed of thin strands of glass, and glass is primarily made of silicon dioxide (silica). Prepared by reinforcing plastic matrix by fine fibers of glass: Fiberglass is commonly used as a reinforcement material in the form of fine glass fibers embedded in a plastic matrix, creating a composite material. Used to make space suits, boats, roofing pipes, etc.: Fiberglass is widely used in various applications, including space suits, boat construction, and the manufacturing of roofing pipes, due to its strength, durability, and lightweight characteristics. Optical fiberOptical fiber, also known as fiber optic, is a thin, flexible, and transparent fiber made of glass or plastic through which light signals can be transmitted over long distances. It is a technology that uses the principles of total internal reflection to transmit data in the form of light pulses. Asbestos fibersAsbestos fibers are composed of long, thin mineral fibers. Chrysotile, also known as white asbestos, is the most common type and accounts for the majority of asbestos used globally. Asbestos has excellent heat resistance and was widely used in various industries for its fire-retardant properties. Blended fibersBlended fibers refer to textile fibers that are made by combining two or more different types of fibers to create a material with improved or desirable characteristics. This blending is done to get the positive properties of each individual fiber, resulting in a fabric that combines the best features of each component. Commonly blended fibers include: Polyester-Cotton Blend: Combining the durability and wrinkle resistance of polyester with the breathability and comfort of cotton. Wool-Acrylic Blend: Blending the warmth and natural properties of wool with the lightweight and cost-effectiveness of acrylic. | |||

Types of MaterialsWe may use many materials in our daily life. Some are made up of natural materials such as wood, cotton, stones and clay. A material can be used to make different kinds of things. For example: glass can be used to make bowls, tumblers, window panes etc. Types of Materials : | |||

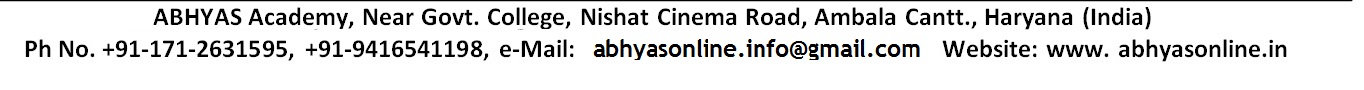

Natural FibresAdvantages of natural fibres:-Disadvantages of natural fibres:- | |||

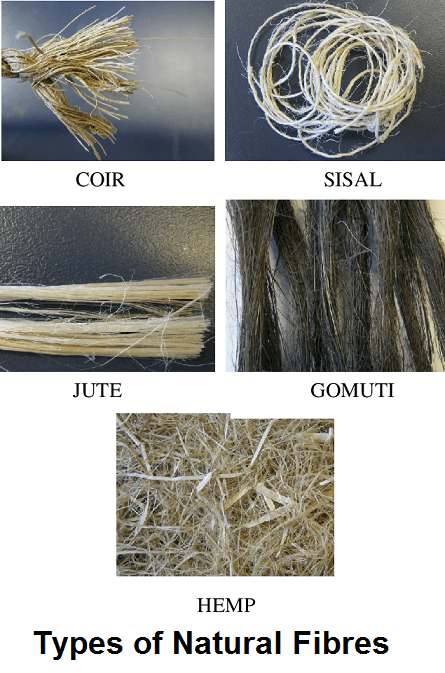

Synthetic FibresHuman made or Synthetic FibresFibers that are made by man from chemical substances are called synthetic fibre. Example: Rayon, Nylon etc. The synthetic fibres are mostly obtained from petroleum. The fabric made up of synthetic fibres is called synthetic fabric. Types of Synthetic Fibres : Depending upon the type of chemicals used for manufacturing synthetic fibres, there are four major types of synthetic fibres (or man - made fibres). These are : (i) Rayon. (ii) Nylon (iii) Polyester, and (iv) Acrylic. NOTE : Rayan is a man-made fibre made from a natural material called cellulose (obtained from wood pulp) Nylon, polyester and acrylic are fully synthetic fibres which do not require a natural material (like cellulose) for their manufacture. These fully synthetic fibres are prepared by a number of processes by using raw materials (or chemical compounds) of petroleum origin, called petrochemicals. Advantages of synthetic fibres:-Disadvantages of synthetic fibre:- | |||

Mixed FibresFibres made by blending natural fibres with synthetic fibres to obtain more superior and useful fibres are called mixed fibres. Examples :Terrycot (Terylene + cotton) :-By observing the term now terrycot is a blended fabric made of terylene and cotton. Terylene is a popular form of polyester, which can be drawn into very fine fibres. Terry wool (Polyester + wool) :-Terry wool is a blend of polyester and wool. Terry wool is actually a mixed fibre because clothes make completely from . polyester is uncomfortable to wear. uses: Terry wool has been used for blankets, horse rugs,saddle clothes, carpeting insulation and upholstery. Terrysilk (Polyester + Silk) :-It is made up of polyester and silk. | |||

Rayon Silk Properties and UsesIn Class 7th, we studied that silk is a natural fibre oblained from silkworms. The fabric (or cloth) made from natural silk fibres is very costly. But the beautiful texture (feel, appearance, shine) of natural silk fabrics fascinated everyone. So, attempts were made to make silk artificially which would be cheaper than natural silk. Towards the end of 19th century, scientists were successful in obtaining fibres having properties similar to that of silk. This fibre was called rayon. Rayon is often regarded as artificial silk. Rayon is a man-made fibre prepared from, a natural raw material (called cellulose) by chemical treatment. The cellulose required for making rayon is obtained from 'wood pulp'. So, we can also say that rayon is obtained by the chemical treatment of wood pulp (which contains cellulose). Rayon is produced as follows :Rayon is different from truly synthetic fibres because it is obtained from a natural material (wood pulp). Although rayon is obtained from a natural resource called wood pulp, yet it is said to be a man-made fibre. This is because it is obtained by the chemical treatment of wood pulp in factories. Rayon fibre is chemically identical to cotton but it has shine like silk Since rayon resembles silk in appearance, therefore, rayon is also called artificial silk. NOTE : Rayon is also called artificial silk, has a silky texture and is prepared from cellulose. The original raw material cellulose is broken down and then reformed in the lustrous fibre called 'rayon'. Rayon was the first synthetic fibre formed from natural raw material. As it is prepared from cellulose so it is not a true synthetic fibre. It is known as semi - synthetic fibre. Properties :-Uses :- | |||

Nylon Properties and UsesNylon is the first true synthetic fibre. It was the first synthetic fibre produced chemically. It was discovered by Wallace Carothers in 1931. Properties:-Uses :-

| |||

Polyester Properties and UsesPolyethylene Terephthalate (PETE or PET)It is a well known polyester polymer. This is also known as terylene or dacron. They are made from petroleum products. Terylene, dacrons and terene are polyester fibre. Polyester clothes are long lasting, water and wrinkle resistant and are of different types. The most commonly used polyester is Terylene. It is blended with natural fibres to improve its properties. Among synthetic fibres the polysters, are most widely used. They account for about one- half of all synthetic fibres. Properties Uses Polyester is another synthetic fibre. Actually polyester is the general name of synthetic fibres which contain many ester groups. Polyester (poly+ester) is made up of the repeating units of a chemical called an 'ester' (Esters are the organic chemical substances which give fruits their sweet smell). We can now say that polyester is a synthetic fibre in which the polymer units are linked by ester groups. Terylene is a popular polyester fibre. The chemical compunds (or monomers) used in making polyester fibres are made from petroleum products called petrochemicals. Like nylon, polyester is also a thermoplastic polymer. When molten polyester is forced through the tiny holes of a spinneret, then thin polyester fibres (or polyester threads) are formed. The polyester yarn can be woven to make fabrics. PET can be made into a fibre or a plastic. In discussing synthetic fibres, PET is generafly referred to as 'polyester' while the term PET is usually used for the plastic form. PET as a plastic is very lightweight. It is naturally colourless with high transparency. PET is strong and impact-resistant. As a plastic, PET is replacing materials like glass.(Unlike glass, PET is shatterproof. PET is used for making bottles, jars and utensils. For example, PET bottles are used for fizzy drinks and PET jars are used for storing sugar, salt, spices and rice, etc.., in our homes (see Figure 4). PET is also used for making thin films and many other useful products. It is clear that polyester fibres and PET bottles and jars are made of the same material.

| |||

Acrylic Properties and UsesAcrylicAcrylic fibre also called Orion and Acrylon, closely resemble wool. Acrylic is a synthetic fibre. Acrylic fibre is made from a chemical called 'acrylonitrile' by the process of polymerisation. Properties :-Uses :- | |||

Spandex Properties and UsesSpandex is a lightweight, soft smooth synthetic fiber which has a unique elasticity. Spandex is made of synthetic polymer called polyurethane which has extraordinary stretch ability. Spandex, also known as Lycra, was invented by the DuPont chemist Joseph Shivers in 1959. Properties :-Uses :- | |||

| |||

Powered by ABHYAS ChatBOT.

What describes you best?

I am a Student

I am a Tutor

I am a School Owner

I want to appear for Govt. Exams

.png)